Tube flaring and tapering

The process of tube flaring and tapering consists of a tube deformation from a larger diameter to an inferior one, with a gradual reduction until the end of the tube. The tube swaging, on the other hand, is the reduction of a tube diameter but just until a certain point. Then the radius does not change.

At Ricos, we build in-house tapering tooling to be then inserted in the tapering machinery and at the same time, a machine group inside our company is ready to supply our clients with a process for tapering or flaring available for any kinds of tube: with different diameters (with a maximum of 80 mm) and with different shapes (square, rectangular, triangular, rhombic, pentagonal, hexagonal and so on).

Different materials are also available: steel, stainless steel, but also aluminum and zirconium copper chrome. This wide range of choices allows us to support our customers in the realization and manufacturing of a personalized product while keeping the entire production process under control.

Tube tapering is a useful process in many sectors: among them the paper industry, the food industry, the lighting field for aesthetic reasons, the hydraulic, the construction industries, and many more.

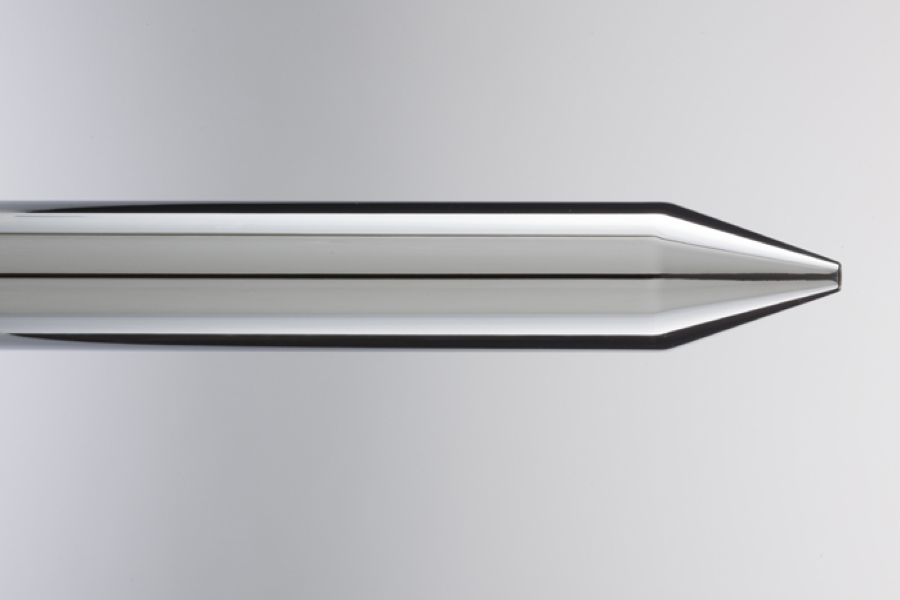

Round metal tube tapered and flared.

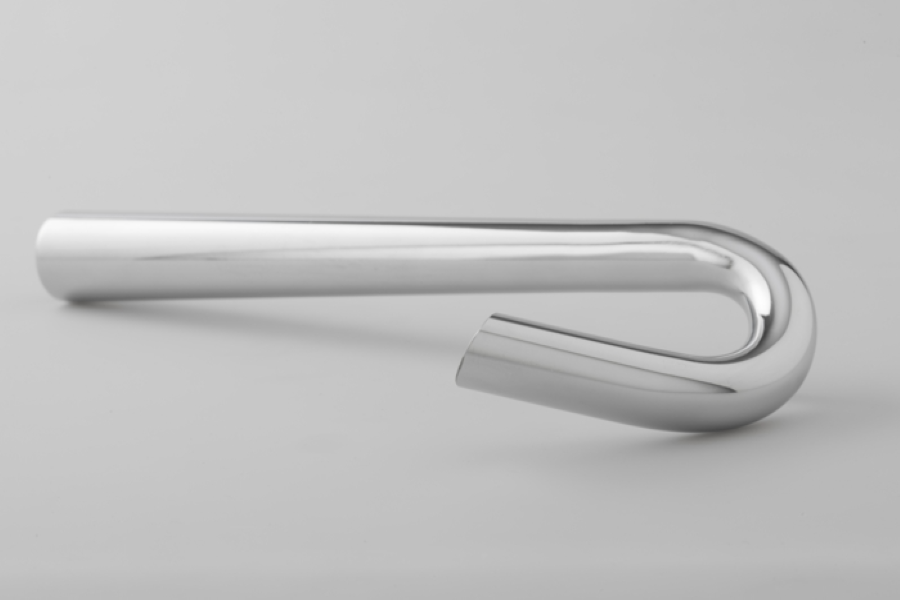

Conifica e curvatura di tubo tondo.

Particular tapering process, from a round to an oval shape, with a reduced diameter.

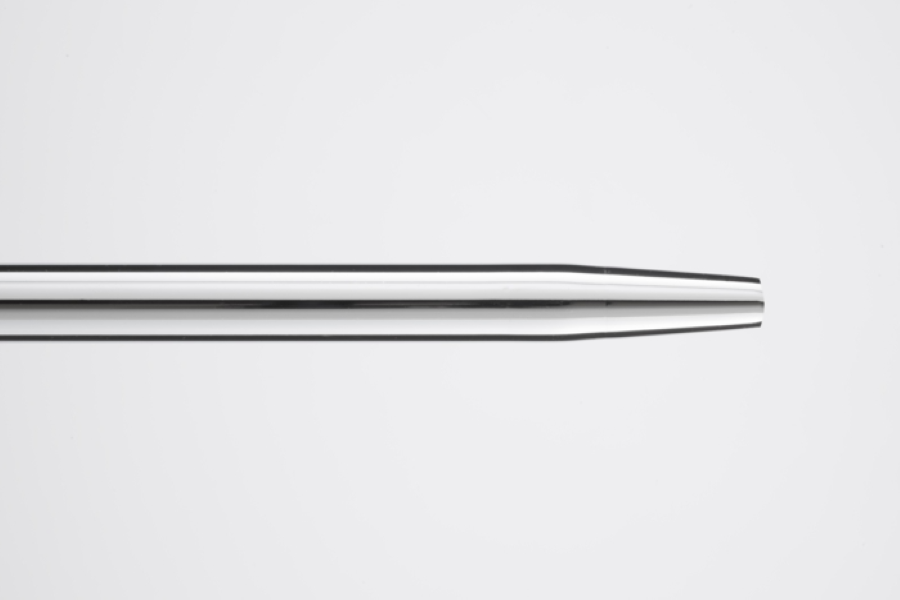

Tapering process of a round tube.

If you want to receive more information about our tube tapering service or a personalized quote, send us your requests using the form below, we will contact you as soon as possible.